Twintec

MANUFACTURERS

TWINTEC

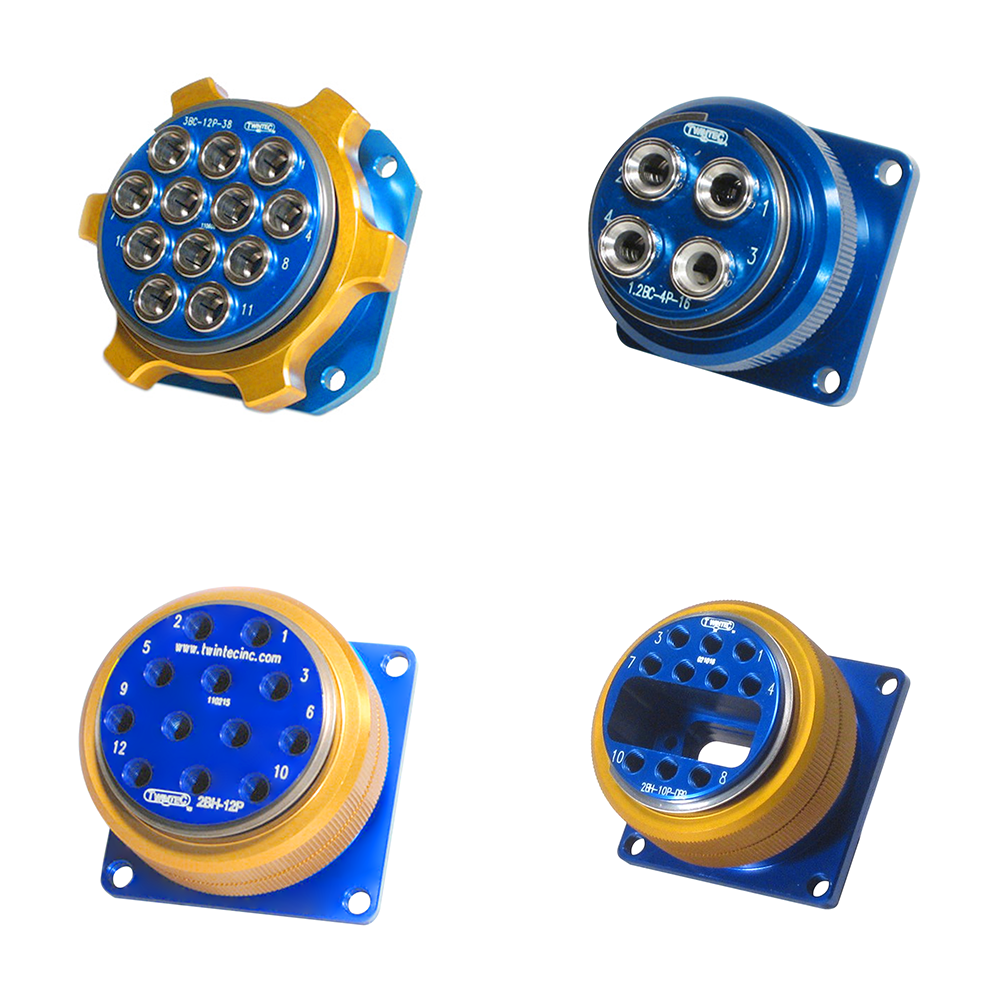

Twintec manufactures precision made multi-tube connectors for quick connecting and disconnecting of pneumatic and air hose applications. Twintec multi-tube connectors enable quick changeover of panel mount and in-line connections resulting in efficient and reliable one-touch installation and removal of nylon and polyurethane tubing. Twintec’s one touch installation and removal of the multi-tube manifold are perfect for lean manufacturing processes.

Fast, Simple, & Accurate

The multi-tube connector manifolds, connectors, and accessories provided by Twintec are fast, simple, and accurate. Twintec’s products can connect in seconds for fast operation and quick changeovers. They provide efficiency by containing all tubes in one bundle and accuracy with the unique design, which prevents misalignment during the connection process. Twintec offers a variety of options to fit your particular lean manufacturing needs.

Standard & Custom Connectors

Twintec multi-tube connectors have solid aluminum construction suitable for many industrial applications while maintaining cabinet integrity. Controls and tooling can be manufactured separately at the best supplier and then brought together.

Twintec Multi-Tube Connector Features:

Time

- Fast operation for quick change-overs

Simple

- All tubes are contained in one bundle and connected in one operation

Enhance

- Regular maintenance and repair; tooling and equipment sections can be swapped out quickly and worked on away from the production environment

Jacket Adapters

Our jacket adaptor accessory provides the means to protect and contain your tubing bundle along with the fitting interface of the connector. Select the adaptor one size up from the minimum size for best results.

Versatile Vacuum Technology

Twintec manufactures precision made multi-tube connectors for quick connecting and disconnecting of pneumatic and air hose applications. Twintec multi-tube connectors enable quick changeover of panel mount and in-line connections resulting in efficient and reliable one-touch installation and removal of nylon and polyurethane tubing. Twintec’s one touch installation and removal of the multi-tube manifold are perfect for lean manufacturing processes.

Twintec quick connect multi-tube connectors are designed to reduce installation costs and prevent tubing misalignment during the conversion process. The Twintec product line has a broad variety of product options and capacity to fit your particular needs. Please contact us directly to learn how Twintec quick connect multi-tube manifolds can work for you. Streamlining and lowering your manufacturing costs is just a “click” away.

Push-to-Connect manifolds are best suited for situations where there is only one size of tubing per connector. The Push-to-Connect manifolds eliminate the added step of installing fittings, which saves time while increasing simplicity. Our Push-to-Connect fittings are suitable for common tubing materials such as nylon and polyurethane. Push-to-Connect manifolds are available in four body styles, 1.2 inch series with up to 4 ports, 2 inch series with up to 12 ports, 2.5 inch series with up to 19 ports, and 3 inch series with up to 24 ports. Ports available are 1/8″, 5/32″, 1/4″, and 3/8″. Metric is available with 4mm, 6mm, 8mm, and 10mm ports.

Threaded Port connectors are best suited for situations where there are variable tubing sizes and the quantity, type of tubing and need for special fittings are not yet determined. Threaded port connectors are ideal for prototypes. Threaded Port connectors come in four body styles, 1 inch series with up to 7 ports, 2 inch series with up to 19 ports, 2.5 series with up to 22 ports, and 3 inch series with up to 19 ports. Available ports include 10-32,1/8″NPT, 1/4″NPT, and 3/8″NPT. M5 is available as an option for most of our 10-32 port connectors.

Our jacket adaptor accessory protects and contains your tubing bundle along with the fitting interface of the connector. For best results, select the adaptor one size up from the minimum size. The jacket adaptor works with spiral wrap, braided wrap, tubing, and vacuum hose. See the How to Use page for assembly instructions.

Contact Flotronics Automation

If you have any questions regarding our services or components, or if you need assistance designing a custom solution, please contact our experienced team at Flotronics Automation by filling out the form below.

We Have the Capacity to Engineer Any Solution!

Flotronics Automation – East

4260 Giddings Rd.

Auburn Hills, MI 48326

Flotronics Automation – West

Tel: (616) 682-7013

- Pneumatic Valves & Fieldbus

- Pneumatic & Electric Actuators

- Pneumatic FRL & Accessories

- Fittings & Tubing

- Vacuum & End Of Arm Tooling

- Motors Drives & Gear Boxes

- Linear Systems

- Connectivity

- Sensors

- Safety Components

- Power Supplies

- Structural Aluminum

- Guarding

- Conveyors

- Enclosures

- Tables & Workbenches

- Application Assemblies

Copyright © 2024 Flotronics Automation. All Rights Reserved.